Automation: large versus small series

No production process is the same. Nevertheless, these can be divided into two categories: production of large series and small series. Each category requires a different automation solution.

- Automation of large series. This is product specific automation. Robot integration takes place: the robot becomes part of the production process and always performs the same operation.

- Automation of small series. This requires flexible automation. The machine with which parts are made is automated. In this way, the operator can set up the machine for a specific product or series.

Cellro specializes in automating high mix, low volume production processes. That means small series. In this article we will specifically discuss this type of production process.

What are the conditions for automation of my company?

- Automation brings a lot of benefits to your business. At the same time, it is an investment (which pays for itself within two years). So it is important to get the process right. There are a number of conditions that your company must meet. Of course, this relates to the CNC machine(s) that you want to automate. However, you also need to take a much broader view: automation has an impact on all business processes.

- Your CNC machine(s) is/are suitable for robot automation and prepared for it.

- Your product portfolio allows for automated production.

- You are aware of your employees’ new way of working (and your employees see the added value of this).

- You adapt your logistics and planning to the automated production process.

Impact on the entire company

Do you want to automate? Then check out all your business processes. See this as an opportunity to optimize these business processes. Current users of Xcelerate confirm this. For example DMF Dietvorst Machinefabriek: “Automation has brought our company to a higher level. You are going to take a good look at your business processes. Products and processes are now accurately defined. As a result, we also see opportunities for automation of other products”.

It is important that all aspects of your production process are compatible with automation. Take the logistics. If your CNC machine runs for more (unmanned) hours, you will also have an increased production output. And so you need an adjusted planning for that. Your suppliers and customers need to be informed about this. Good preparation is therefore half the work. Also with automation!

The benefits of automation for your business

As mentioned before, automation offers many advantages for your company. But what exactly are they?

- More production hours. Also at night and in the weekend your CNC machine produces series! These are productive hours, without labour costs. Via a job manager, the machine operator can program several series in a succession. This also maximizes the unmanned hours.

- Higher efficiency manned hours. The robot is the “assistant” of the machine operator. This allows the machine operator to operate multiple machines at the same time. The robot takes over the serial work (such as inserting a workpiece each time).

- More challenging work for staff. The machine takes care of serial work. This allows your skilled personnel to engage in more challenging work.

- Increased product stability. A robot doesn’t make mistakes. Therefore, if it is set correctly, the robot will always perform the correct operation. This reduces the chance of errors in the process.

- Responding to market demands. Automation allows you to supply products faster. Customers demand flexibility from their supplier, and flexible automation certainly helps. Moreover, automation increases your delivery reliability and quality.

Cellro offers customized solutions

Cellro understands the impact that automation has on your business and guides you through the entire process. We speak from experience. Our roots are in the machining industry. Metal processing is therefore in our DNA. Years of expertise enable us to offer you tailor-made solutions. Flexibility is our core value. Our robots move with your company!

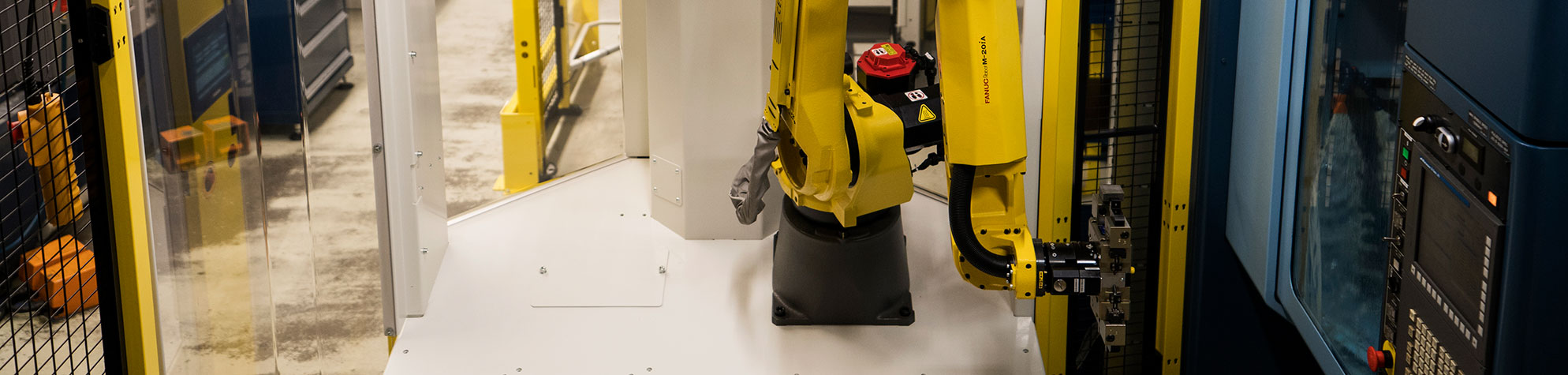

Xcelerate: flexible par excellence

Xcelerate is the ideal match for high-mix, low-volume production processes. This robot is easy to move and can therefore be connected to multiple CNC machines. This allows you to get even more out of your automation. You can also decide when Xcelerate is connected and when it is not. In principle, the CNC machine can still be used as usual. In the manned hours, the operator can run specific production as usual or, for example, adjust new work, while at night the machine continues to run production thanks to Xcelerate. Because of this flexible automation you are always prepared for market demands. After all, as a company you often do not yet know what you need to produce in two months time! At the same time, the automated process guarantees the quality of your production.

Elevate: To the next level

Elevate has a very high capacity of product storage, on as small a floor space as possible. By storing the products on so-called ‘trays’, a high variety of products can be handled flexibly. Elevate can operate one or more turning, milling or other type of machines. The coupling with the machine is intensive. The operator controls both the machine and the robot. This requires a different level and a different way of working by the operator. In any case, the work becomes more challenging.

HMI: a dialogue with the machine

All Cellro robots are equipped with an HMI (Human Machine Interface). We therefore do not use robot programming. This means that your employee can operate the machine without any problems. Robot knowledge is not required. Cellro’s HMI is very ingenious and at the same time accessible. Moreover, it is linked to metalworking. Step by step, the machine operator can program new series via the HMI. It is in fact a dialogue with the machine. The result is a flexible and optimised production process.