Collaborative robot and robot both have their qualities

First of all, choosing a cobot instead of a robot is not necessarily better or worse and vice versa. It is comparing apples with oranges. To make that clear, it is good to know what a Collaborative robot (cobot) is and what it can do and compare that with the functionalities of a robotic cell. What is ultimately the best option for your business depends on what you want to use this piece of automation for.

Cobot provides support for operators

Collaborative robots are designed to work together with humans. The difference with a robot is that they are usually designed to work independently in an automated way. The purpose of a cobot is to provide support to operators’ work or perform single operations. A cobot, is a full-fledged robot that allows it to work independently but also in combination with humans. So for literally taking certain labour-intensive and repetitive tasks off your hands, a cobot is perfectly suited.

.

.

An important advantage of a cobot is that, compared to an industrial robot, they are safer in a small environment where people are working. This has everything to do with their compactness and thus more mobile application, sensitive detection sensors that immediately stop the cobot when touched, and the lower power and speed at which a cobot operates. Especially from a support role, for which a cobot is often used for loading production machines and assembly, this safety aspect is not unimportant. The great accuracy and consistency with which a cobot relieves operators of a lot of monotonous work and the direct and indirect benefits this provides for a company mean that cobots have become indispensable in many machining companies. The cobot price also plays an important role in this. Cobot automation is considerably cheaper than robot automation in terms of investment.

The difference is in the functionalities

Like a cobot, a robot can perform tasks independently. However, the real difference is made by the complete automation of which a cobot or robot is a part. This is where the more extensive functionalities of a robot cell compared to a cobot come into their own. Think extra power and speed, automatic gripper changing, more storage capacity and therefore more unmanned production capacity.

Add to this the fact that through the Cellro interface (HMI) robot systems are already prepared for workpiece handling. So only the job needs to be configured. With a cobot, you have to programme the flow and all subsequent steps yourself. So actually the difference is not so much in the cobot or robot itself but more in the preconditions, the configuration of which a cobot or robot cell is part. Because of the extra functionalities, a robot system provides extra flexibility and more production capacity with the existing machinery and without additional personnel. The disadvantage of a robotic system is that it requires shielding in the form of, for example, a floor scanner or fencing, due to safety in the work area. This takes up extra working space.

.

.

Cobot automation complements robot automation

If a cobot is used for what it was developed for, it is certainly an excellent investment. Purchasing a cobot, especially by SMEs, is often seen as a low-threshold way to get acquainted with the benefits of automation. By and large, a cobot can do exactly the same as a robot, except that a cobot system is more limited in terms of functionalities and programming takes more time. Companies already familiar with automated production sometimes consciously choose to purchase a cobot as the missing link within their production department.

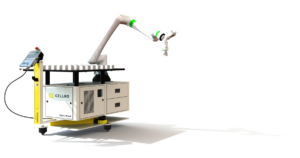

Comate from Cellro, low-threshold and flexible

Comate from Cellro, low-threshold and flexible

Cellro has further lowered the threshold to automation with the addition of Comate to its product portfolio. This FANUC-cobot integrated solution has a handling capacity of 10 kg. Users can choose either the standard FANUC Cobot controller or the Cellro HMI prepared for flexible production for machining companies. In short, with Comate from Cellro, you can : get in low cost without compromising on user-friendliness and flexibility.

Calculating investment and payback period

Significantly increasing the number of spindle hours for costly CNC machines often comes up during discussions with entrepreneurs. This applies to companies that are not yet familiar with automated production, but also to parties that want to take the next step. The questions of what this will cost and how quickly the investment will pay for itself are always discussed. It would be short-sighted to choose a cobot purely because of its lower price. On the other hand, it is also true that an industrial robot is by no means the best solution for every automation issue. As mentioned, it depends on several factors. What do you want to do with it, how large unmanned production capacity is desired and do you already take future automation expansion possibilities into account?

Cello will be happy to help you find a suitable answer to your automation problem, which of course includes an ROI calculation with a clear and realistic foundation. The fact that, in many cases, a thorough client-specific analysis and ROI calculation show that robot automation is the best and often the only option, has everything to do with both the extra functionalities and the possibility to expand automation in the future in a relatively simple way. For dynamic manufacturing companies, the capabilities of a cobot system are often too limited.

Cellro offers the best cobot and robot automation

With Comate, Xcelerate, Elevate and Ultimate, Cellro offers high-quality robot and cobot automation solutions for small, medium-sized and large machining companies. These systems can be flexibly expanded with additional functionalities, such as Fixture Exchange and Collet Exchange, Job Manager, exchangeable and adjustable grippers and a centring and reversing station. For more information and advice, please contact us.