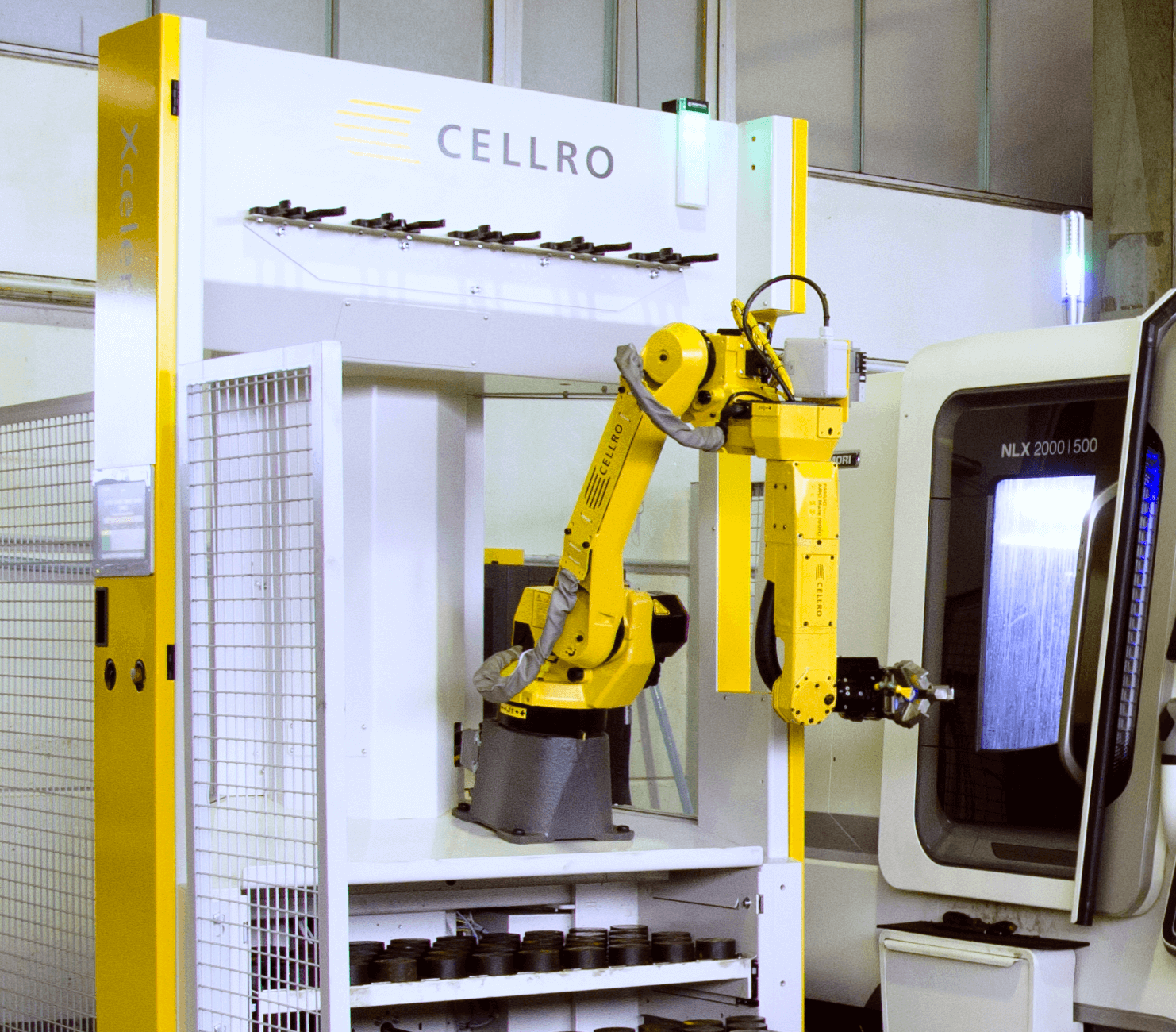

Flexibility in your automation process

With Xcelerate and Elevate, it is always possible to automatically load one or more series with similar work pieces. With Collet Exchange and Fixture Exchange, you are able to exchange the machine vice or the collet without the intervention of an operator. The size of the machine vice or the diameter of the collet therefore no longer determines which work pieces can be processed with automation. Therefore, you can process various product series with work pieces that have very different dimensions, unmanned, with your CNC machines.

Ideal for suppliers

If you supply to many different companies, flexibility and speed are important competitive issues for your organisation. Due to the large variation in, and unpredictability of, your production process, you likely did not have the luxury of carrying out your production at night using automation before. With Fixture Exchange and Collet Exchange, you can also process small and varied series, unmanned. Xcelerate and Elevate have enough capacity to store all your unprocessed and processed products with various dimensions and with the clamping technology of Hainbuch you are able to change collets and machine clamps quickly and easily. As a supplier, you are able to meet the demands of your client more quickly. In addition, you can take on several different assignments. In the daytime, during the manned hours, you have enough time to take on more complex serial work.

Fixture Exchange: unmanned product handling for milling machines

Product handling is a method of automation that is already frequently used for lathes. Fixture Exchange expands on product handling and allows you to process various different product series on a milling machine, unmanned and one after the other. A single pallet with machine vices that can be automatically exchanged is sufficient to allow flexible production with your milling machine. In addition, this option is more financially advantageous than pallet handling. Many companies will consider it risky to have unsupervised switching between different product series on a milling machine. By testing the first run of each product, you can be sure that the automated exchange from one product to another using Fixture Exchange is working smoothly.

Fixture Exchange and Collet Exchange: simple to use

Including Fixture Exchange or Collet Exchange in your production and automation process is very simple thanks to Cellro’s user-friendly software. Often, clients believe that they must have technical specialists in-house who can program the robot loading systems — but that is not the case. Loading a CNC machine with a robot loading system from Cellro is generally very simple.

However, you do need to consider that an extra step will be added to your production process. You need to know beforehand which machine vices and collet are required to enable you to process the planned series. Make sure you do not pair the wrong series with the wrong machine vices or collet. This will prevent your production from coming to a standstill. We recommend that you plan as many of the same type of series back to back and limit the number of changes in machine vices or collet required. Complex series that require your attention should be planned in the daytime, so there is an operator on hand.

If you invest in Fixture Exchange or Collet Exchange, some adjustments must be made to your robot loading system. Furthermore, you must have the required machine vices and collet that can be automatically changed during your production process. Most companies already have the necessary components. Since you are able to continue producing for longer, you can quickly earn back your investment in Fixture Exchange and Collet Exchange. The speed at which this will happen will, of course, depend on your production.

Can Fixture Exchange or Collet Exchange be used with my CNC machine?

Fixture Exchange uses a zero-point clamping system to clamp the machine vice onto the pallet. This is the most common method used to clamp work pieces in the machine industry. Most milling machines are therefore already fitted with a zero-point clamping system. In addition, your CNC machine must also be able to receive NC numbers. With NC numbers, you can tell the machine which tools it must use for each product series. Since this requires greater communication with your machine, this can usually only be done with newer machines. In some cases, it’s also possible to install Fixture Exchange and Collet Exchange on existing machines, but the specialists from Cellro must first determine the adjustments that must be made to your machine.