Impact at product level

By work process, we primarily mean loading and unloading of machines, such as CNC lathes, milling machines, wire cutters, etc. These are all valuable machines that should stand still as little as possible. Cellro’s automation solutions are therefore aimed at achieving as many ‘spindle hours’ as possible with your machine park. It is our challenge to put together the most suitable automation application for you. Will Xcelerate, for example, do perfectly, or is Elevate, Modulerate or the Ultimate better suited to the work process in your company? However, these four products have one thing in common. Programming the software is very easy!

Impact in terms of ease of use

The better the automation matches your machine park and the work process in your company, the greater and more positive the impact will be. We advise you on this and of course ensure that the automation is carefully implemented. We will also explain to your employees how to operate the software. Furthermore, we are available for support whenever you need it. Simplicity is our starting point and an optimal return for your company is our goal.

Impact on efficiency

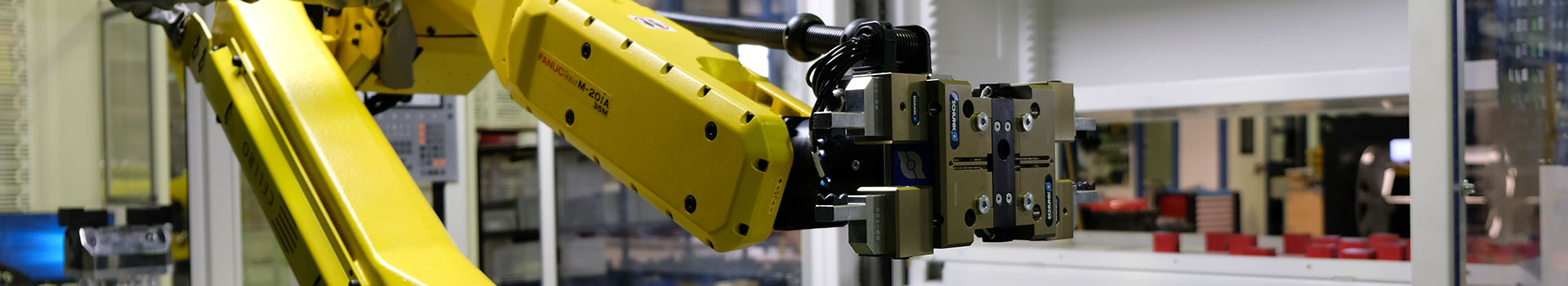

Fanuc robots are used on all our automation systems. A major difference between the systems is the maximum load capacity of the robots. With Xcelerate it is 20 to 70 kg and with Ultimate the robot can lift up to 360 kg. Other factors that determine the difference in impact are the storage capacity for raw and processed material, the possibility to connect one automation to several machines and the option to combine both product and pallet handling in one automation. Whichever option is chosen, everyone in your company can configure the desired settings. The control’s interface is logically laid out and very clear. Once you have seen how it works, you can start using it.

Financial impact

An important question for entrepreneurs is what the impact of automation is in financial terms. What does it cost and what does it give you? We have a calculation module available for this purpose. With it, we can show the extent to which the spindle hours increase and the labour costs decrease. In companies that run 24/7, the impact will naturally be the highest. For example, customers report that Cellro’s automation solutions have doubled the number of spindle hours. Think your production runs are too small for automation? A customer recently told us that he leaves a series of 5 products – even with a short run time of only a few minutes – to the Elevate. The automation takes care of everything and gives him peace of mind. It could work the same way for you!

Watch the video here in which Dirk shows you how easy it is to set up the programming of our automation. Or contact us to discuss the possibilities and to calculate the costs and benefits for you.