Automation for small and medium-sized companies

It is almost unavoidable for small and medium-sized companies to deploy a robot in their production process. Do you need to take on a full-time robot programmer to implement a robot into your production process? No, that’s no longer the case. There is now a way to keep up with the larger companies, who deploy robots in droves. Today’s robot systems are actually very different from their predecessors dating back to the Eighties. Recent innovations in robot control systems can now allow almost any company to benefit from the potential of automation. Specialist staff no longer need to be engaged thanks to the user-friendly, universal software.

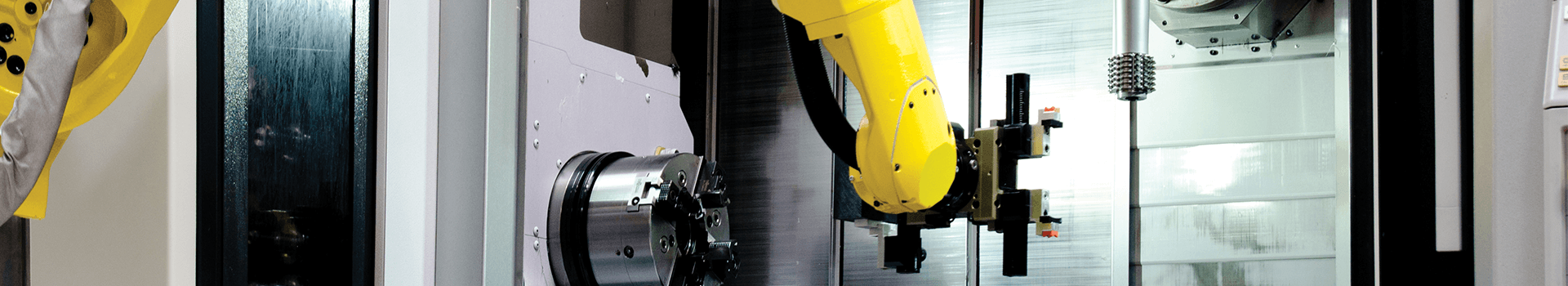

Robots for CNC machines: ever-wider deployment

The growth in the deployment of robots in the machining industry continues unabated. Since the ‘robot boom’ in the Eighties, robots have undergone dramatic developments. Initially, robots only took on simple, repetitive tasks. Nowadays, in the age of Industry 4.0, robots are also able to perform a variety of tasks autonomously and process different work pieces dynamically. This evolution is extremely important for small and medium-sized machining companies. Indeed, they usually work with relatively small product series. Cellro loading robots can switch between a variety of product series in a fully automated manner. Xcelerate and Elevate are able to easily change over tools, clamps and robot grippers. As a result your production hours go up significantly, even with small and medium-sized series. When you decide to automate (part of) your production, your business will benefit in a number of ways. Every hour, your CNC machine will return a larger profit for you and continue to operate for more hours each day, even extending into the night. This ensures that any investment in combining a CNC machine with a robot quickly pays for itself, even for small and medium-sized machining companies.

No programming knowledge required with Cellro robots!

Using traditional robots, small and medium-sized companies are seldom able to exploit the full potential of automation. Admittedly, these companies can cut back on labour, although this time is in turn taken up on programming the robot. Moreover, trained specialists need to be recruited who have the required programming know-how for these complex assignments. This is far from ideal as many small and medium-sized machining companies just don’t know today what they will be producing tomorrow. Cellro therefore advises against investing in an automation system that requires programming know-how. No programming know-how is required to connect a Cellro loading robot to your CNC machine!

User-friendly software: the key to success

The design of Cellro’s loading robots for CNC machines is particularly well-suited for small and medium-sized companies. No programming knowledge is required to control robots and to allow the robots to process different types of products. In this process, the software acts as a ‘translator’ between the user and the loading robot. All you have to do is specify what must be done through easy-to-use touchscreen controls. Then the software tells the robot how it needs to proceed.

In practice, this means you only have to input product size, quantity, location and clamping method. Other tasks are fully automated. Take, for example, opening and closing drawers, controlling the pneumatic grippers, opening the door of the CNC machine and launching programs. In short, there are two important reasons why small and medium-sized companies can also make the transition to automation:

- No programming know-how is required for automation.

- Loading robots are able to process different types of products thereby keeping downtime to a minimum.