Suitable for various product lines

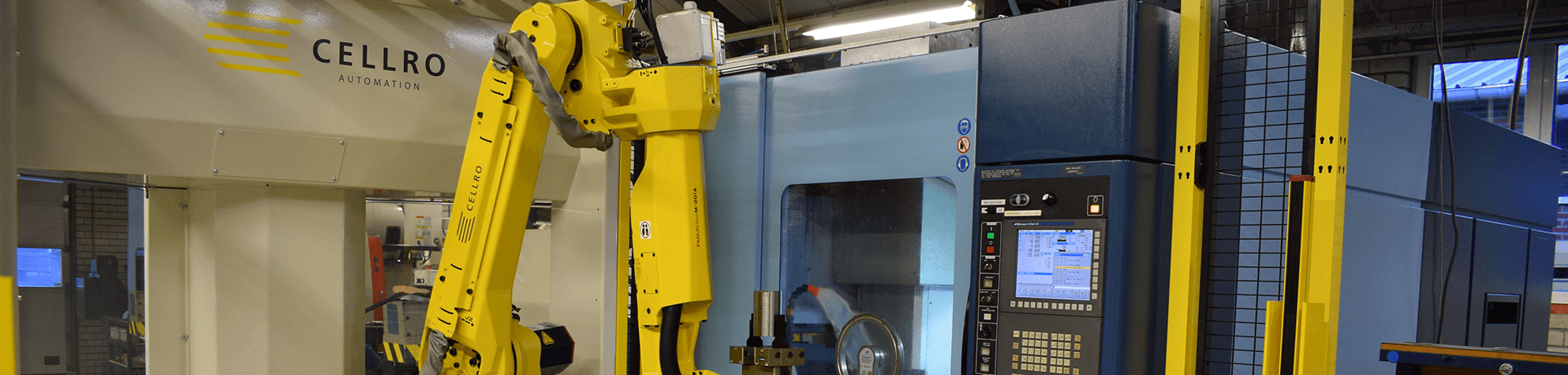

Cellro leads the field in automating the loading process for various types of CNC machines such as milling machines and lathes. Cellro offers a comprehensive range of robot loading systems, capable of handling loads from 10 to 250 kg, with a wide range of functionalities. The purchased product configuration can be expanded with additional functionalities later on as desired. The initial threshold is low, but you remain prepared for the future. The flexibility of your robot automation is permanently assured. This means there is a suitable loading system available for products and lines of many, many different sizes.

Are you unsure whether your machine process is suitable for robot automation? Please see our tips.

Increase your production output by 85%

Xcelerate and Elevate are excellent examples of robot loading systems that will increase your production output by 85% on average. The main reason is that in combination with robot automation, the machine can continue production unmanned through the night. Medium-sized lines can be loaded onto the machine without the need for an employee to be present.

Real-life examples of robot automation

Cellro has helped various machine shops with their robot automation. For G.A.B. Metaal, a metalworking firm, the implementation of two Xcelerates resulted in 200 additional spindle hours per week. At Debets Mechanical Support, which produces parts for the medical and measurement industries, the number of spindle hours also increased significantly. Not just the higher production output appeals to customers. Xcelerate’s ease of operation is valued as well. For Felder KG, manufacturer of machines for the timber industry, this was the deciding factor in opting for Cellro.