Aufsteigen mit Elevate

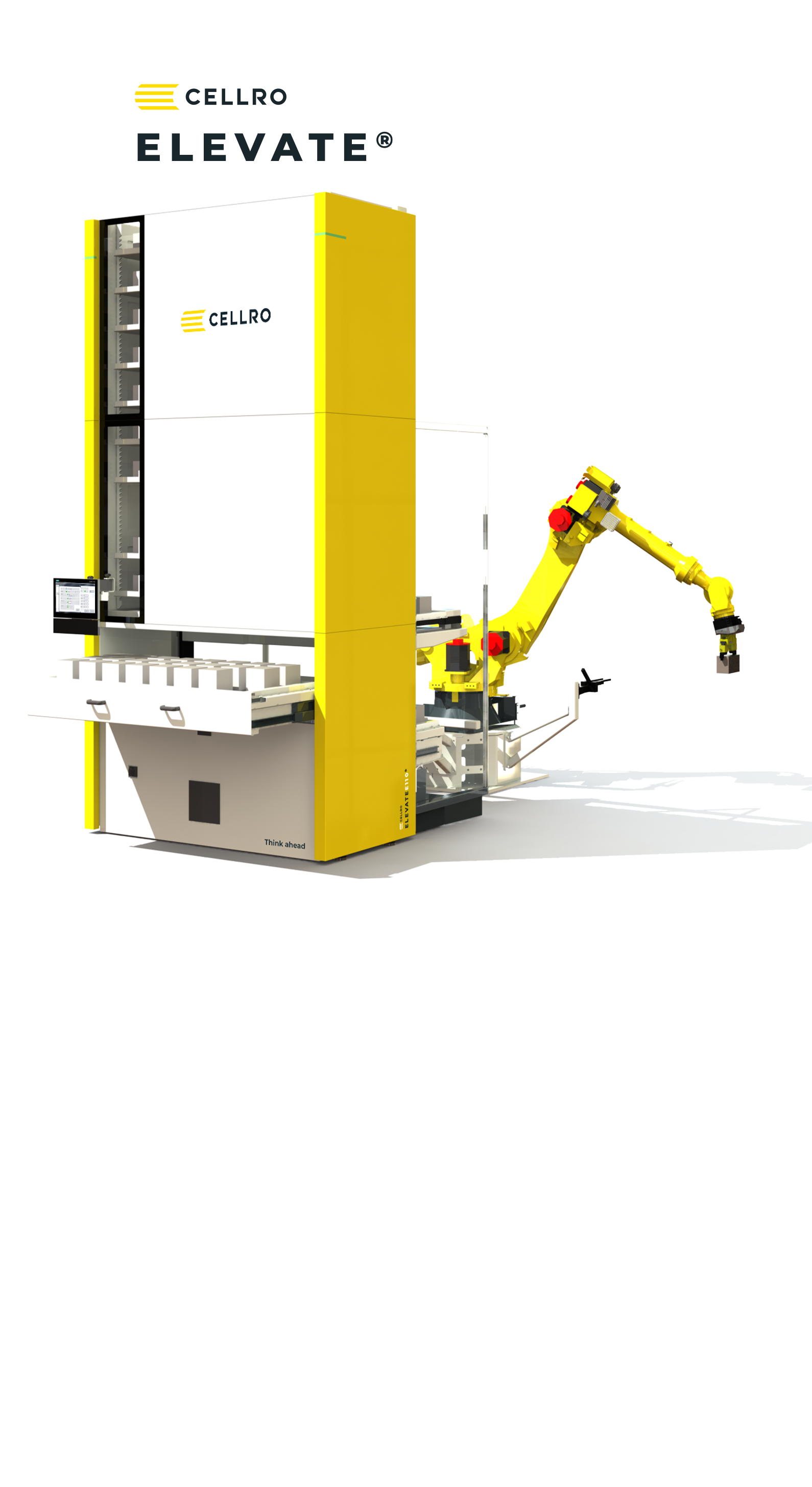

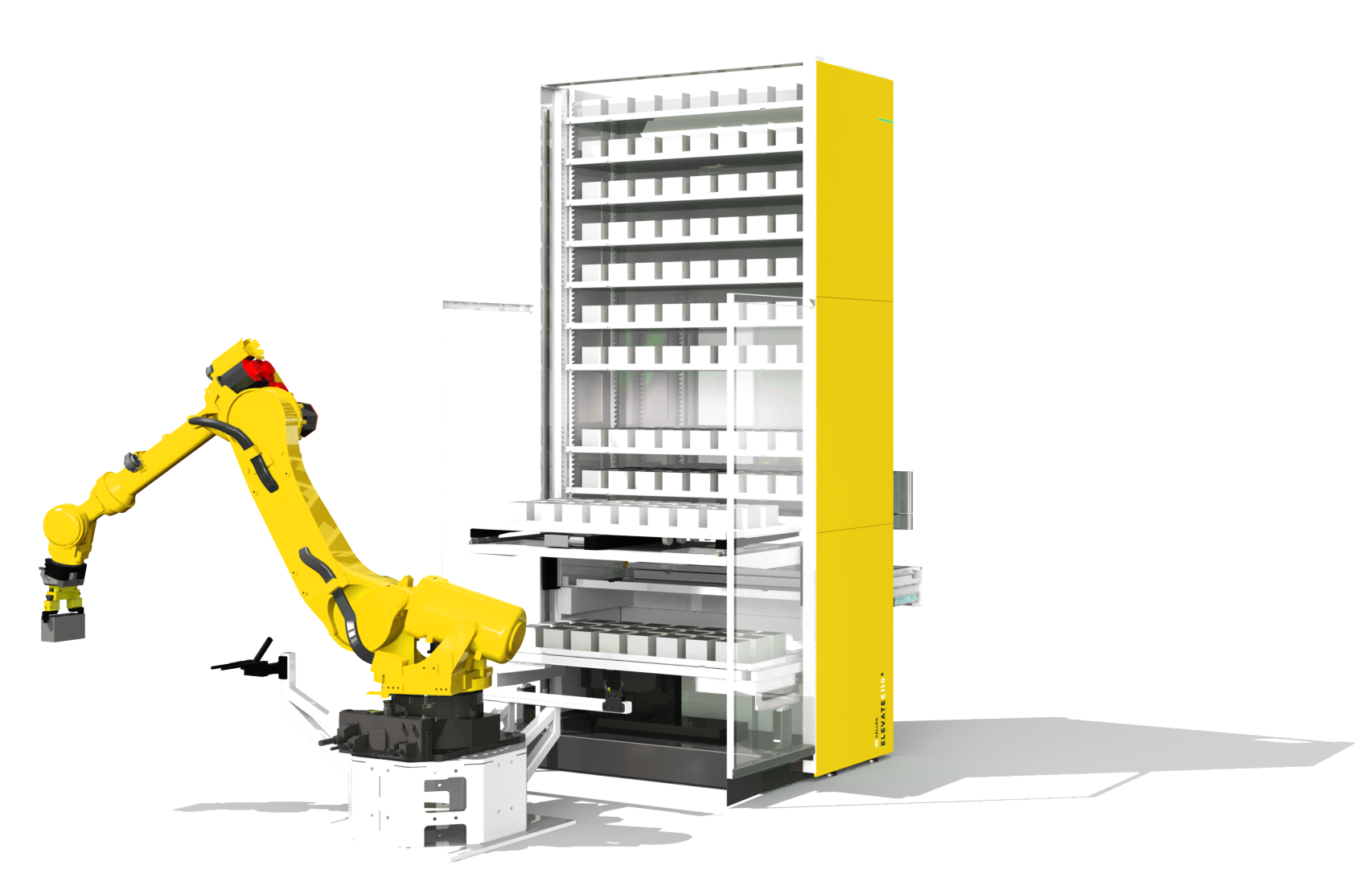

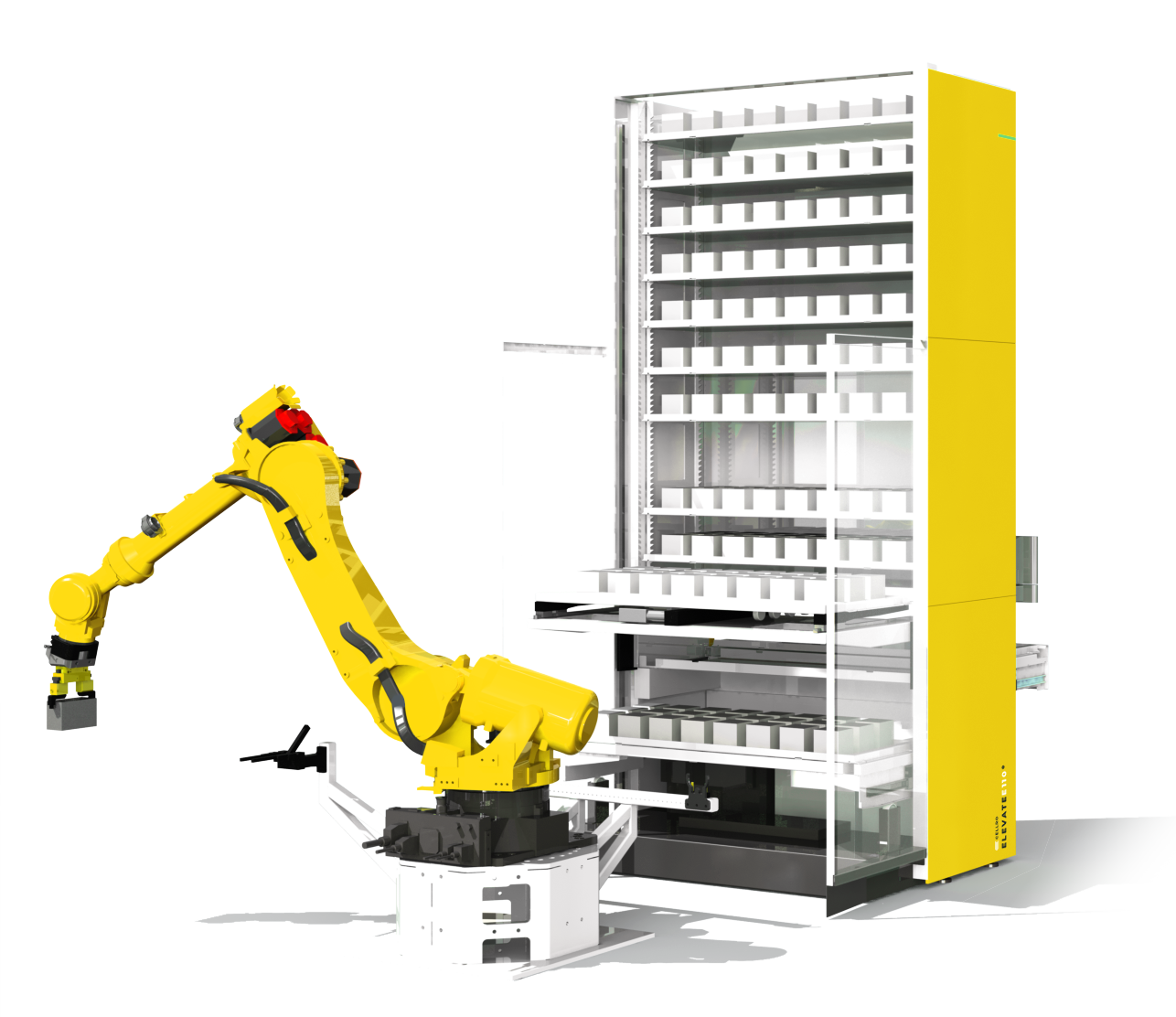

Mit einer Höhe von drei und vier Metern bietet der Elevate eine beeindruckende Lagerkapazität von bis zu 28 Produkt-Trays. Das sind sage und schreibe 24m2 Speicherkapazität. Dabei benötigt das gesamte System nicht mehr als 2,8m2 bis 5m2 Bodenfläche, je nach gewähltem Rahmen und Roboter.

Aber Elevate ist mehr als nur eine Menge Speicherkapazität. Da die gesamte Logistik für die zu verarbeitenden Produkte in Elevate vorhanden ist, ist eine autonome, aber vor allem effiziente Produktion zu 100% gewährleistet. Das System generiert ständig Rückmeldungen für Aufträge, die heute, aber auch in der Zukunft ausgeführt werden sollen. Die Möglichkeit, die Aufträge von morgen bereits mit Elevate abzuwickeln, macht die logistische Herausforderung in der Werkstatt planbar. Auch Kunden mit einem eigenen Produkt haben mit Elevate eine neue Möglichkeit. Anstatt auf Vorrat zu produzieren und das Lager zu füllen, kann nun auf Abruf produziert werden.

Der Einfluss der Cellro-Automatisierung auf den Arbeitsprozess (Hardware)

In zwei Webinaren erläuterten Dirk van Manen und Bram de Koning die Auswirkungen der Automatisierung auf den Arbeitsprozess. In einem früheren Artikel ist Software-Ingenieur Dirk näher auf die verschiedenen Möglichkeiten eingegangen und insbesondere auf die Einfachheit, mit der Sie die Steuerung unserer Automatisierung selbst einrichten können…

Lesen Sie mehr

✔ Auf kleinstmöglicher Fläche die höchstmögliche Kapazität der Produktlagerung.

✔ Ergonomische Ladeposition Produkte können mit Hilfe einer Schublade einfach auf ein Tablett gelegt werden.

✔ Durch hohe Speicherkapazität langfristige Autonomie Ihrer Maschine(n) garantiert.

✔ Große Auswahl an Robotern mit unterschiedlichen Nutzlasen verfügbar, das dieser frei vom Lift steht.

Effizienz auf höchstem Niveau.

Das Smart Storage System, das die Höhe der gelagerten Tablare an die Höhe der gelagerten Produkte anpasst, trägt zur optimalen Nutzung der Lagerkapazität bei. Der Abstand zwischen den Tablaren wird auf ein Minimum reduziert und die Bewegungszeit zwischen Maschine und Tablar wird ebenfalls minimiert. Darüber hinaus kann der Elevate das aktive Tablar vor dem Roboter parken und währenddessen andere Aufgaben erledigen, während der Roboter arbeitet. Auf diese Weise geht keine Zeit verloren.

Besonderheiten

Laden Sie die Broschcre Elevate E80 und E110 herunter, um die neuesten technischen Daten dieser CNC-Automationen zu erhalten.

Warum sie Elevate wählen