Easy to use. Versatile in deployment.

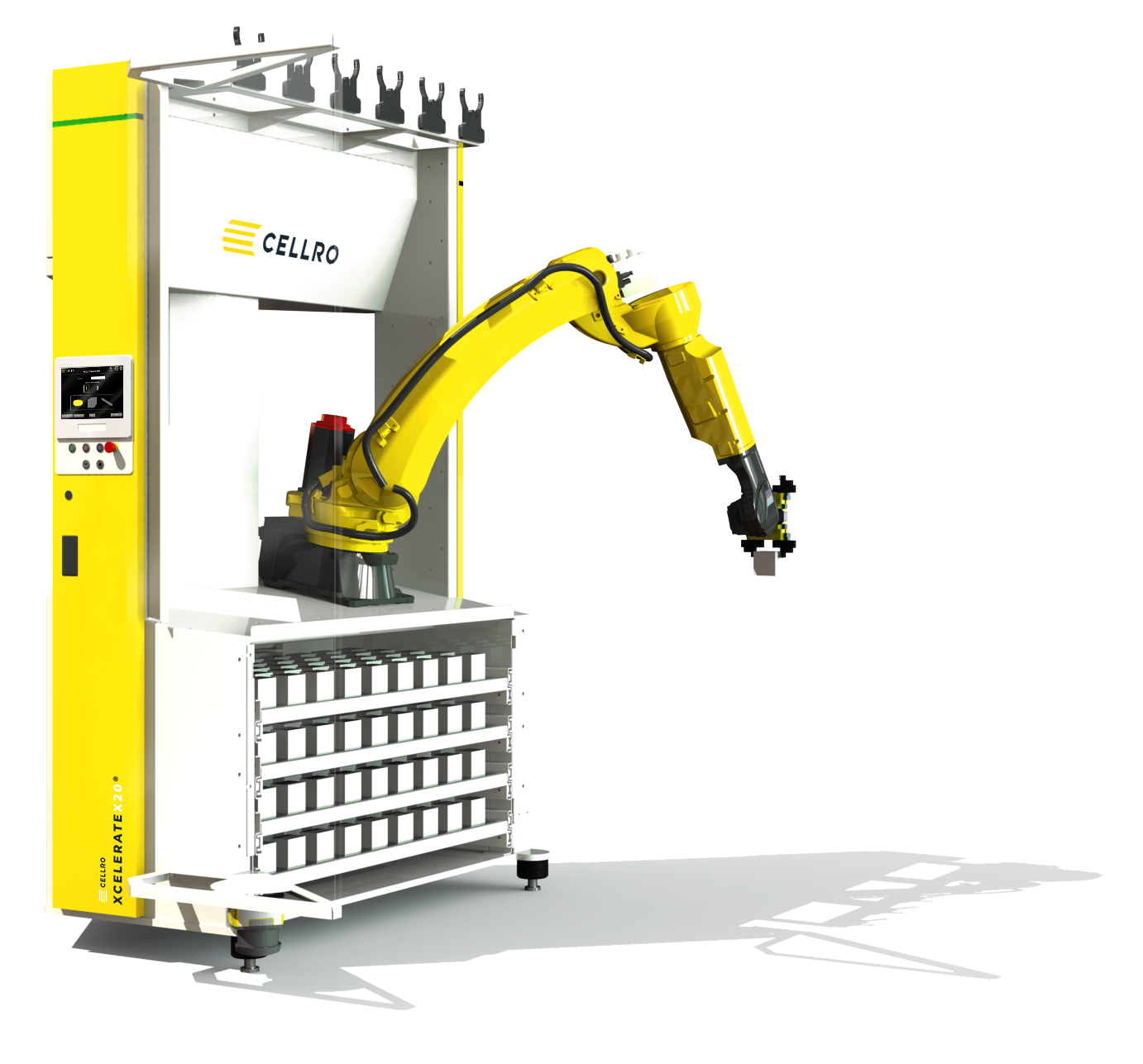

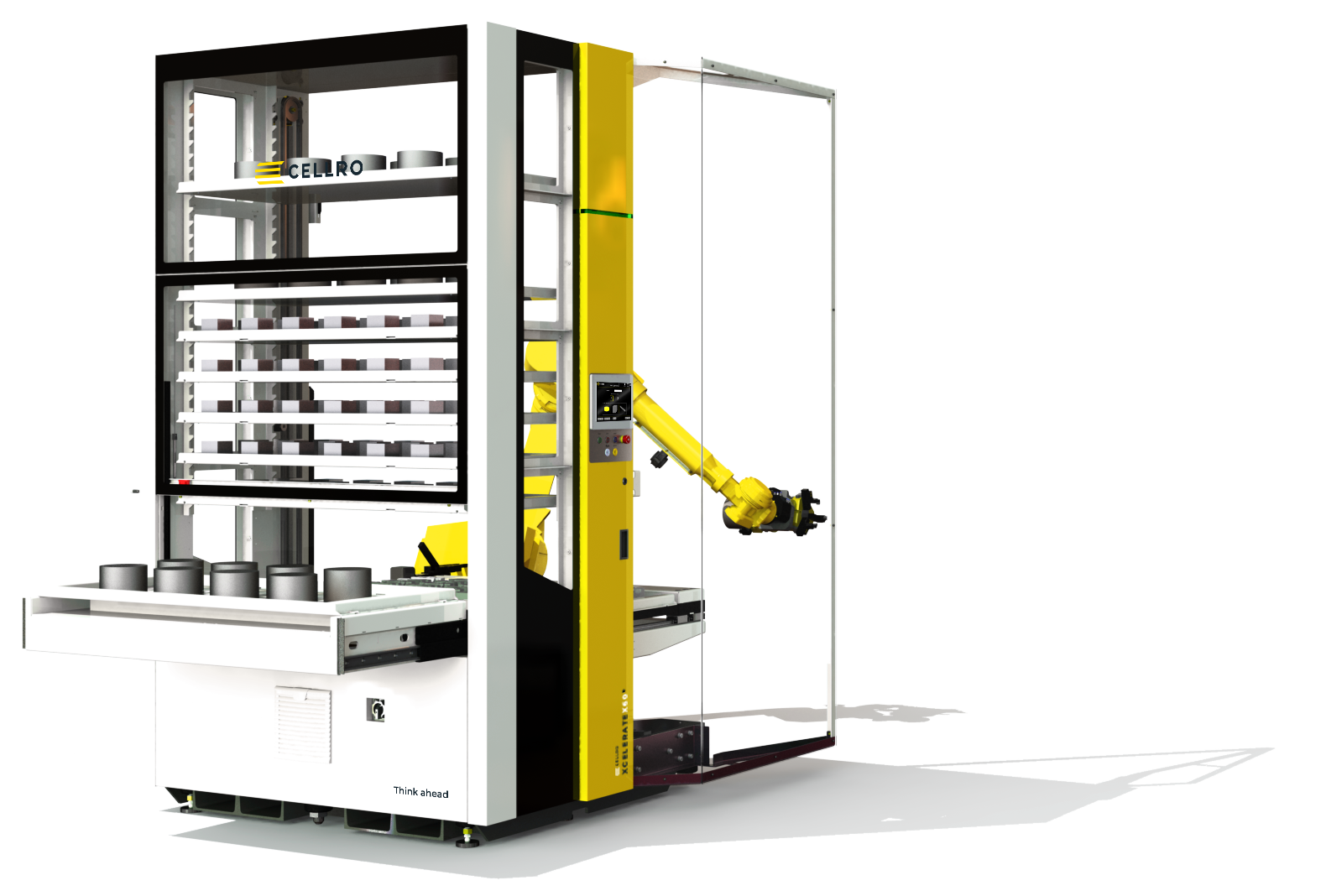

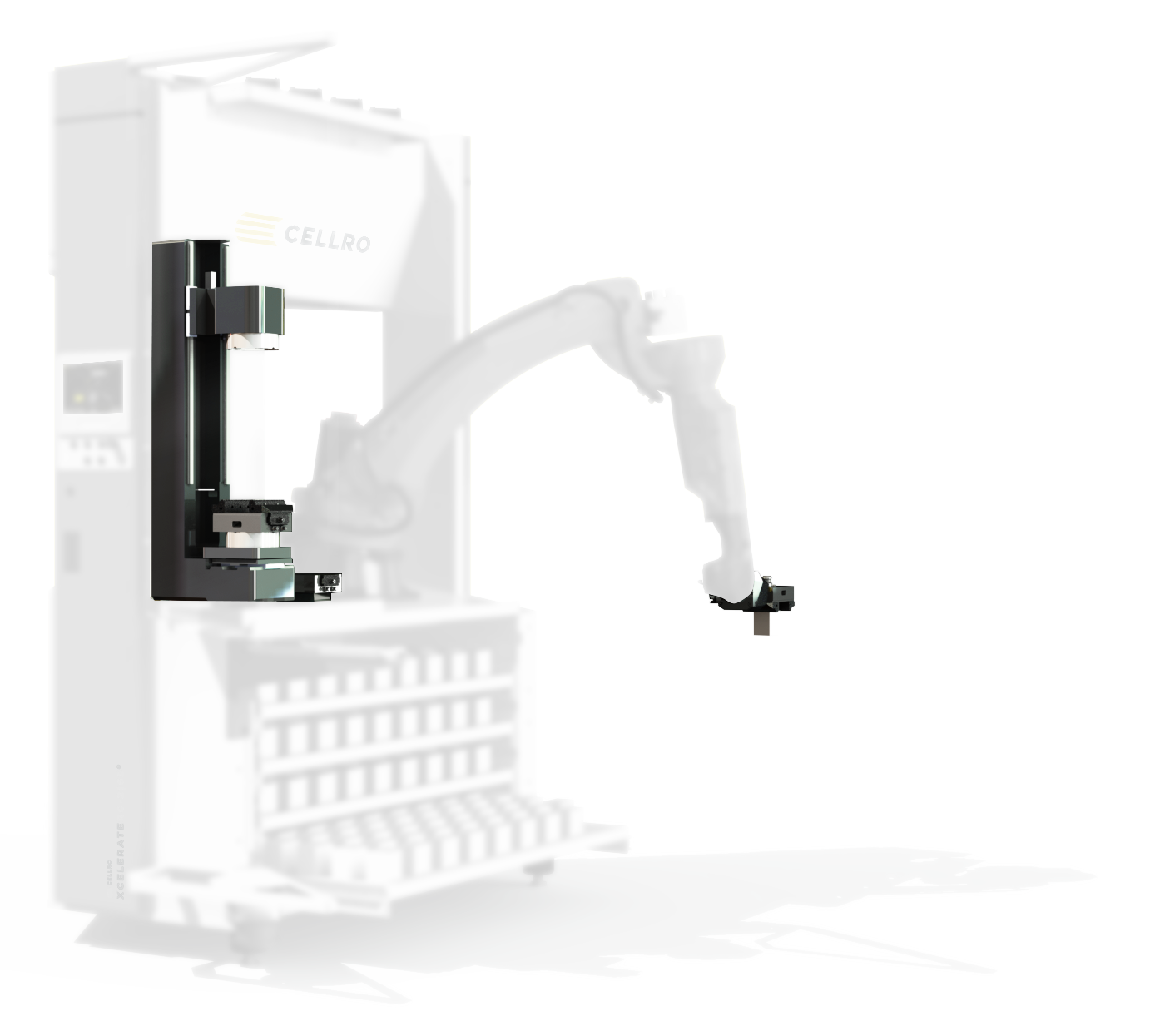

Each standard Xcelerate configuration consists of smart components that provide a high level of functionality and reliability. Round parts, squares, shafts, forgings and castings all fit into the same system.

By using Cellro’s universal product inlays, you can produce with minimal logistical effort. But for a high-runner or casting, you can easily create a product-specific inlay without Cellro.

Your operator sets up a new product in no time with the intelligent Xcelerate control system (touch screen). Moreover, at any time you can see all the necessary parameters for an optimal production process. With the intelligent and user-friendly HMI, the operator can make product-specific adjustments himself.

How to get a reliable production planning

The production process within machining companies consists of countless variables that influence production planning. Cellro’s automation solutions speaks of…

Read more

✔ Compact and portable. Maintain machine access, without adjustments in floor layout.

✔ Can be used on new and existing CNC machines.

✔ Ready to use for diverse operations, turning, milling, grinding and measuring.

✔ Short setup times with the most efficient configuration software on the market.

The benefits of Xcelerate.

At Cellro, the needs of the customer come first. Hence the large product portfolio that Cellro carries. In the conversation with you, your needs of today will be combined with the desire of tomorrow, and in doing so, the right Xcelerate will emerge.

Xcelerate X10, X15, X20, X35 and X60 are all the perfect basis for your CNC automation. With the standard use of gripper change and expandability with cabinets and/or tables as desired, Xcelerate is future-proof. From turning to milling machines and from grinding to measuring machines. Xcelerate ensures that product series are finished automatically. Because Cellro is machine-independent and works closely with numerous machinetool manufacturers, Communication between Xcelerate and your machine can be set up according to all common protocols.

Specifications

Why they choose Xcelerate