The TechniShow is the largest and most important fair of the Benelux in the field of industrial production techniques, processing of metals, plastics, accessories and tools. The TechniShow will take place from 20 to 23 March 2018 in the Jaarbeurs in Utrecht.

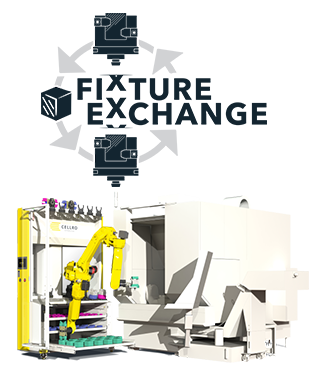

Cellro will be represented at this fair with the Xcelerate automation system: The Fixture Exchange and Collet Exchange are the latest innovations to be added to Cellro’s wider product range. The automation specialist offers a comprehensive product portfolio, with appropriate solutions for a variety of automation desires. Those interested in automation are very welcome to visit the Cellro stand in Hall 10, Stand C50.

Free registration