Schubert Fertigungstechnik GmbH is a subsidiary of Gerhard Schubert GmbH. Gerhard Schubert GmbH is the world market leader in the field of top-loading packaging machines. “We supply them with complex turned and milled parts as well as ready-to-install assemblies. Around 85 employees work at our site in Bartholomä. With a high degree of automation, we show that we can also work economically in Germany,” says Managing Director Jens Grieser.

Conscious strategic decisions

The German company was advised and supported by Cellro in its decision to automate its CNC machines. “With Cellro’s automation solutions, we were able to open up new markets and serve existing customers more quickly. The goal is to achieve at least 5,000 spindle hours per year with the machines. We are well on our way to realising these goals,” says Mr. Grieser.

Maximum benefit through intelligent CNC automation

Technical Manager Bernd Fuchs explains what was the main reason for Schubert Fertigungstechnik GmbH to opt for automation. “We took the first steps back in 2008 with the first machining centre. We wanted to increase our productivity through automation. In addition, the use of robots relieved our employees of heavy and monotonous work. This allows them to concentrate more on process optimisation and quality assurance.” Schubert Fertigungstechnik was the first to opt for the Compact, which is installed on a DMC 1850 V, where the R-C2 module from Gressel is also used. This system convinced us, as we can very flexibly manufacture different products in an automated, unmanned way.”

User-friendliness as additional motivation

As a skilled worker and machine operator, Markus Schick experiences the advantages of automation on a daily basis. “The robot processes components in small batch sizes between 5 pieces and 50 pieces. The robot is very flexible, I have room here for 6 different vises, 5 drawers in which I can process 5 different products one after the other. The operation of the control system is very simple. The programmes and drawers are selected via a touch screen. Markus Schick then loads them and the automation processes the orders.

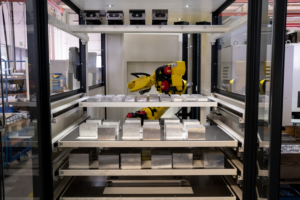

Ultimate is invaluable

Bernd Fuchs explains why Schubert GmbH also opted for a second solution from Cellro, the Ultimate. “The reason was pallet handling, where we can handle different products in different sizes and variants. The new system is very user-friendly and we have a high degree of variability.” Skilled worker and machine operator Thomas Maier adds. “We are currently working with the Cellro Ultimate, which has 36 pallets and is connected to a DMU 80 Evo. In the future, the plan is to install a second CNC machine of the same design and integrate it into the automation and to expand the control system with additional, new functions. What surprised me personally in a positive way was the simplicity of the overall system operation.

Schubert Fertigungstechnik appreciates the cooperation with Cellro

Intelligent automation has become indispensable at Schubert Fertigungstechnik GmbH. Everyone involved appreciates the role Cellro has played in this. “Our experience during the commissioning of the Cellro system was that everyone involved worked very closely and professionally together, and the commissioning was successfully completed in a very short time,” says Bernd Fuchs.

Intelligent automation has become indispensable at Schubert Fertigungstechnik GmbH. Everyone involved appreciates the role Cellro has played in this. “Our experience during the commissioning of the Cellro system was that everyone involved worked very closely and professionally together, and the commissioning was successfully completed in a very short time,” says Bernd Fuchs.

Thomas Maier is equally enthusiastic. He is particularly satisfied with Cellro’s service. “The cooperation with Cellro is very good. If a problem arises and we call or send an e-mail, there is immediate feedback, and the fault is solved as quickly as possible. Managing Director Jens Grieser has nothing to add to this, except: “We will not buy any processing machines without automation. We have a defined automation strategy with fixed machine types. We will acquire these as needed and expand our capacities,” he explains resolutely.