On Ultimate you can build.

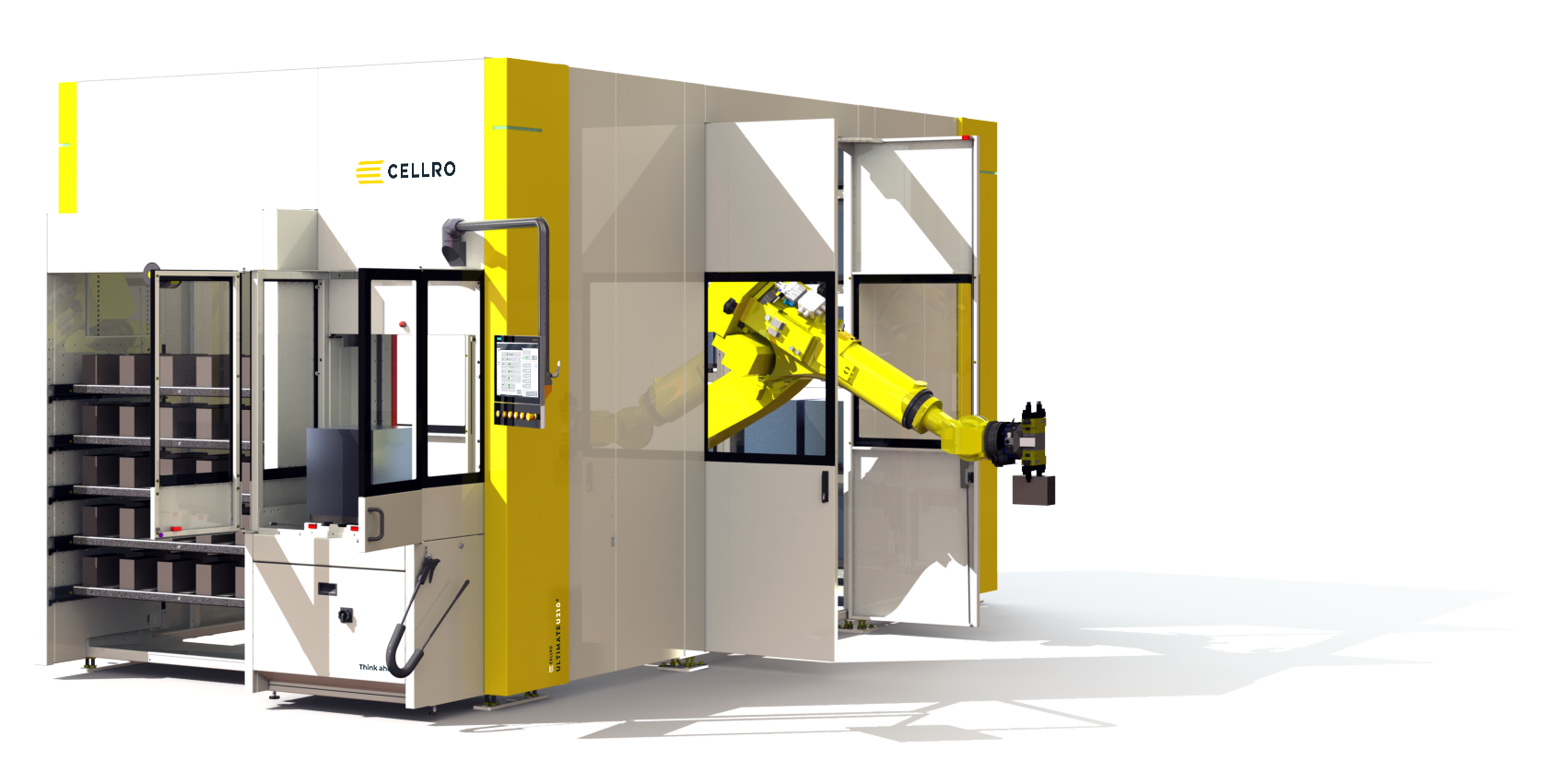

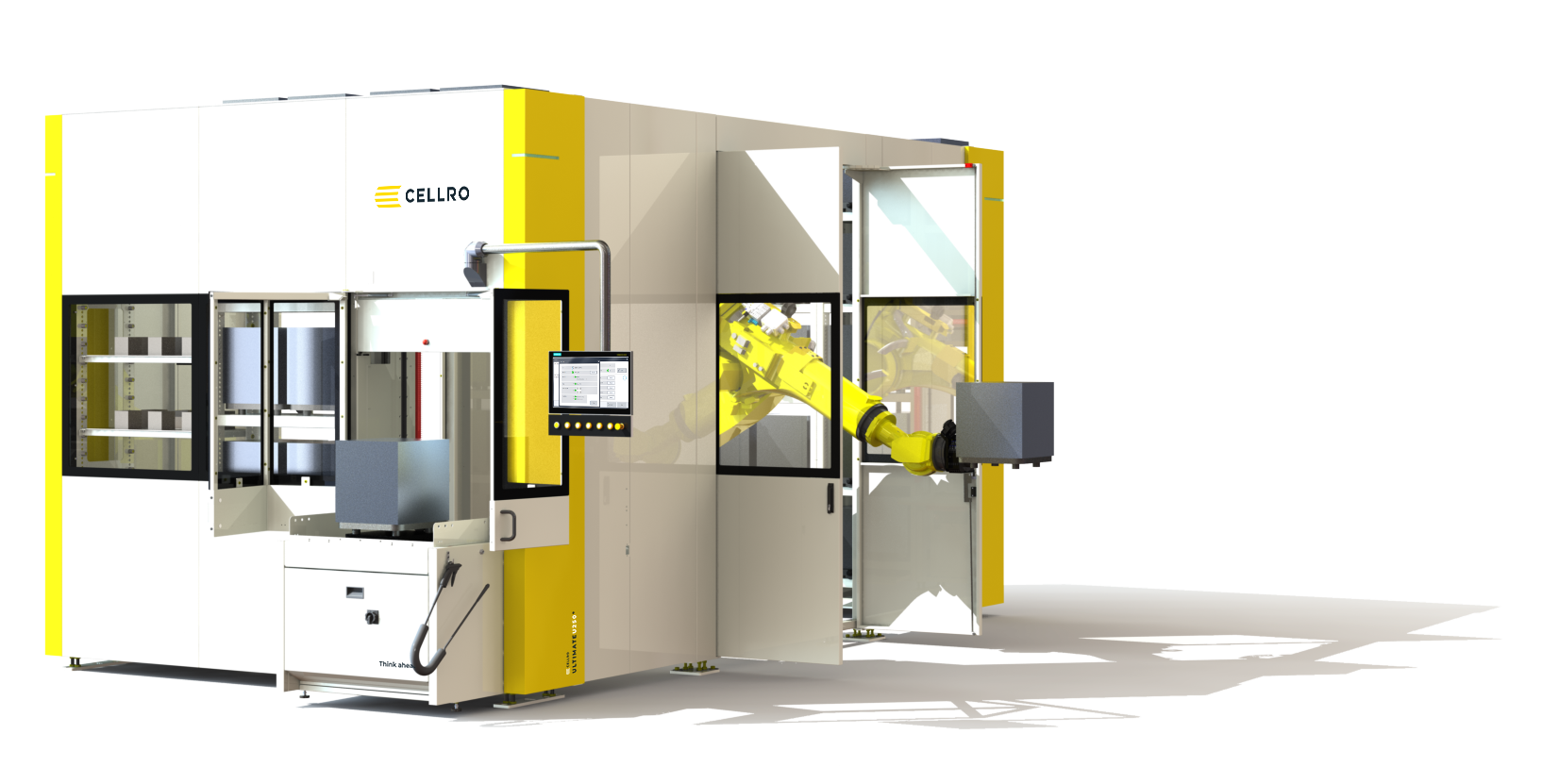

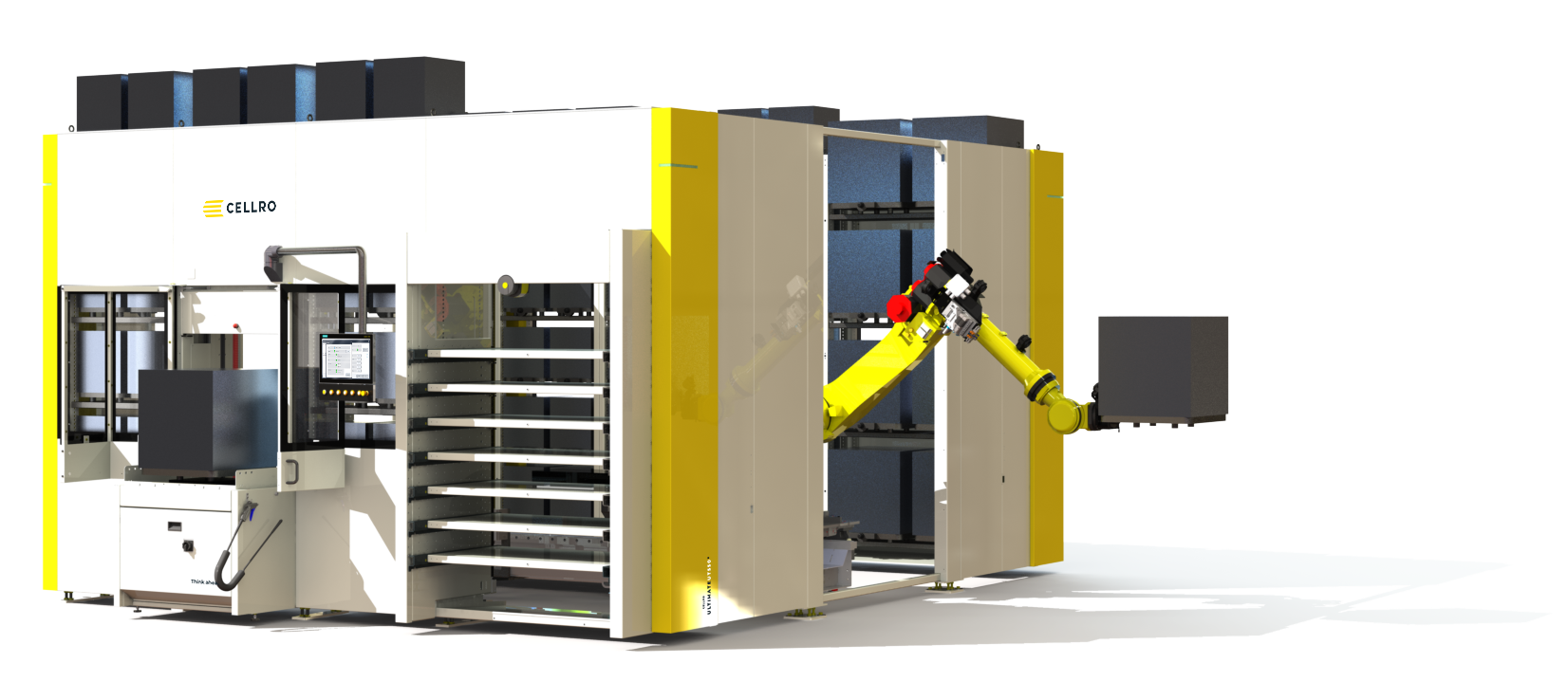

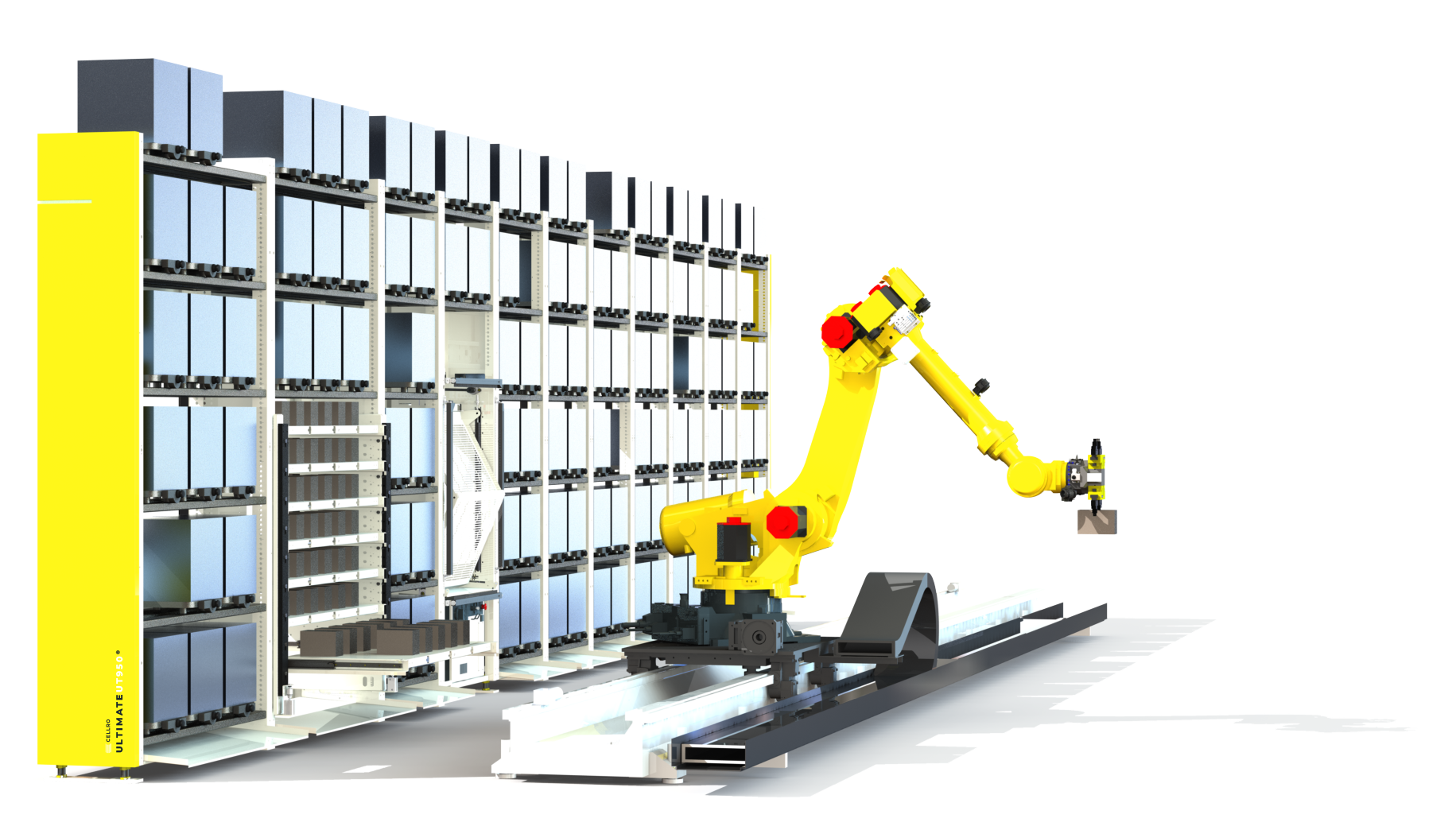

Ultimate flexibility is guaranteed in this modular system for automating milling processes. Due to the variety of convenient building blocks of this CNC automation system, there are various expansion options to create the desired storage capacity and input convenience.

Ultimate has different configurations, but can be adapted and expanded both in functionality and capacity. The functionalities of pallet handling, product handling and also tool handling can be combined in one system. Go for one of the standard configurations or work with the available modules and easily build your custom Ultimate.

The impact of Cellro automation on the work process (Software)

By work process, we primarily mean loading and unloading of machines, such as CNC lathes, milling machines, spark erosion machines, etc. These are all valuable machines that should stand still as little as possible.

Read more

✔ Smart Storage Optimal use of storage space tailored to your production needs.

✔ Ergonomic design Highly accessible loading module, for loading and unloading products, pallets and fixtures.

✔ The unimaginable number of possibilities in mix of products and pallets is processed and tracked by the system.

✔ The system can even integrate a second machine when your future production needs require it.

Comfort serves man.

Ultimate is mostly used for handling single pallets over 125 kg in combination with product handling. Optionally, tool handling can be added if the machine controls can be adjusted accordingly. Ultimate is operated via an intelligent and user-friendly software, which gives the operator a lot of information to optimize the production process and can be integrated with higher-level software layers MES and ERP. By using the machine lock, the machine remains accessible. Ultimate is ideally suited for product series from 1 to 500 pieces. Products that are often handled by Ultimate have a cycle time of 6 to 60 minutes per product. Due to the modularity of the product, Ultimate can be expanded/converted and extended with the robot on a track.

Specifications

Ultimate

Download the Ultimate series specification sheet for the latest technical data on these CNC automations.

Why they choose Ultimate