Dimensions trays / drawers:

- Xcelerate X10: 1000 x 400mm up to 4 drawers

- Xcelerate X15: 1000 x 400mm up to 8 drawers

- Xcelerate X20: 1200 x 600mm up to 4 drawers

- Xcelerate X35: 1200 x 600mm up to 8 drawers

- Xcelerate X60: 1200 x 600mm up to 19 trays

The drawers are pushed out of the frame by servo motors or by the robot in a smooth motion. The controlled movement of the trays allows you to handle a wide variety of product shapes without the need for support. By stacking products (if the shape of the products allows it) the storage capacity is increased.

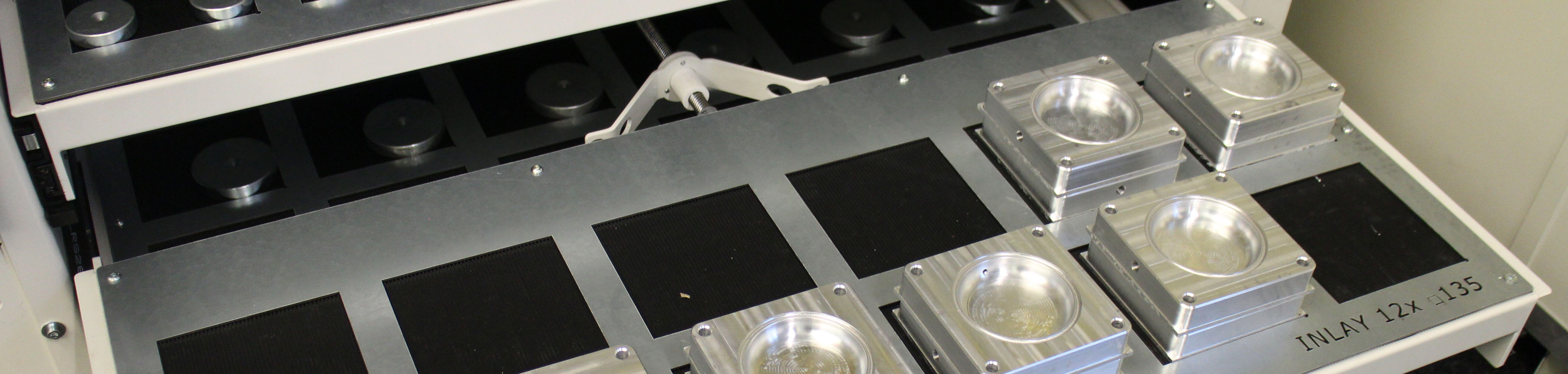

Trays or trays and inlays

Xcelerate can be configured with different combinations of trays and inlays. These depend on the dimensions of the workpieces to be processed. Cellro offers you standard inlays, in which different product shapes and sizes can be placed.

Since you need flexibility in your production, you can also create your own inlays which are compatible with the unique shape of your workpieces, as long as they have a repetitive character. It is important to determine which inlays and how many trays you can use to ensure the longest possible production run without operator intervention.

Depending on your product mix, choose a drawer configuration that is suitable for your production. Do you have work pieces that are higher than the distance between the drawers? No problem. The Xcelerate X10 and X20 control system allows you to lock one of the drawers through the product configuration so that you have twice the available workpiece height in the bottom drawer. Or in the configurations Xcelerate X15 and X35 you can determine the distance between the drawers yourself. With Xcelerate X60 the tray transport ensures optimum product storage based on the individual product height. So Cellro offers you maximum flexibility here too.

Personalisation of inlays and fingers

The inlays and fingers supplied by Cellro with the system are just the beginning of automation. When using the loading robot, you will notice that you can fully customise Xcelerate to suit your production process. Fingers and inlays are custom made for your unique production process. You can also make your own inlays. If required, Cellro will of course offer you support in this. And so, thanks to the modularity, no two Xcelerates are exactly the same.

Carts also form part of the standard package. Carts are used when a production process demands extra flexibility. The need arose when Xcelerate users wanted to the possibility of having a batch prepared while Xcelerate was busy loading the machine. In addition, it appeared that internal transport between different machines is simplified by unloading the raw products from other machines onto the cart earlier in the production process. You can then drive the cart to Xcelerate, where you dock it. At that point, Xcelerate knows – with the help of the installed program – where it can pick up and replace the products.

After processing, it may be desirable to bring the processed products to a subsequent machine for post-processing (if required). This is easy to do with the cart, as the products have already been put back into place there. This solution pays off if you machine the same product on a regular basis. Xcelerate can continue working immediately after changing the carts.

Product carts

Product carts are part of the standard package, mostly used with Xcelerate X10 and X20. Product carts are used when the production process requires additional logistical integration. The need arose when Xcelerate users wanted to have the possibility to prepare a new production run while Xcelerate is loading the machine. In addition, it was found that internal transport between different machines could be simplified by loading raw products from other machines onto the cart at an earlier stage in the production process. You drive the cart to Xcelerate, where you dock it. At this point Xcelerate knows where the products need to be picked up and put back, according to the set program.

After processing, it is sometimes desirable to take the processed products to the next machine for possible finishing. This is easily done with the product cart on which the products have already been put back. This solution is worthwhile if you often process the same product. Xcelerate continues immediately after the carts are changed.

Good to know when using product carts

Since a product trolley is used, the workpieces must be locked in such a way that they do not move within the inlays. In contrast to the insertion of drawers or trays, this is necessary with product carts. For each product, you therefore need a suitable inlay.

A trolley has one level. This means that the Xcelerate can easily handle longer workpieces or products with deviating shapes. The maximum product height for product trolleys is 220 millimeters. Moreover, a product trolley has more weight to carry than a drawer. Are the work pieces together too heavy for a drawer? Then a product cart is a good alternative.

Product carts for X10 and X20

| Product cart | Xcelerate X10 | Xcelerate X20 |

| Number of product carts | 1 | 2 |

| Maximum product height | 200 mm | 220 mm |

| Loading surface per cart | 1000 mm x 800 mm | 600 mm x 800 mm |

| Maximun load per cart | 350 kg | 350 kg |

Want to find out more?

Would you like to know more about loading or trays, inlays, product trolleys from Cellro? Come in contact with one of our experts today. They know the answers to all your questions!